Products Technology, Sustainability

The Demain Jacket: the most eco-friendly technical jacket… and the most technical eco-friendly jacket ever!

Article published on October 9, 2020

What if it was possible to climb the highest mountains wearing waterproof, breathable, AND eco-friendly technical outerwear? Look no further. Picture’s latest technical jacket is armed with the truly innovative and eco-friendly Xpore membrane!

Pulling from the vast expertise of Taiwanese electronics giant BenQ, it took several years of R&D to perfect the Xpore membrane. Today, Picture enjoys exclusive rights to this incredible innovation for the upcoming FW20 season.

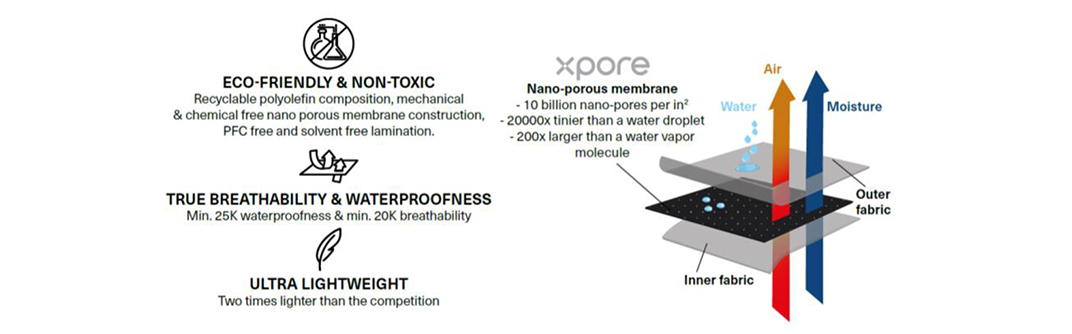

On a technical note, Xpore is made using recyclable polyolefin. The membrane’s nanopores are created through a process of mechanical stretching that does not require the use solvents or PFCs, a major difference when compared to more “traditional” methods. When it comes to performance, the membrane posts statistics that are simply off-the-charts, with a minimum waterproof rating of 25k and a minimum breathability index of 20K grs. In addition, Xpore is incredibly lightweight, making it the most sustainable and highest performing membrane to date.

Focus on the Demain Jacket

The close collaboration between Picture and Xpore produced the high-end, 3-layer Demain jacket, specifically designed to perform during rigorous adventures in any weather. And to take our approach several logical steps further, in addition to the eco-friendly membrane, we used bio-sourced materials for this incredible jacket’s face fabric, a sugarcane waste derivative unsuitable for human consumption. For more information about bio-sourced materials, click here. The Demain jacket has broken the mold in the outdoor industry by combining high-performance with sustainability for the very first time.

Waterproof-breathable membranes, a quick review

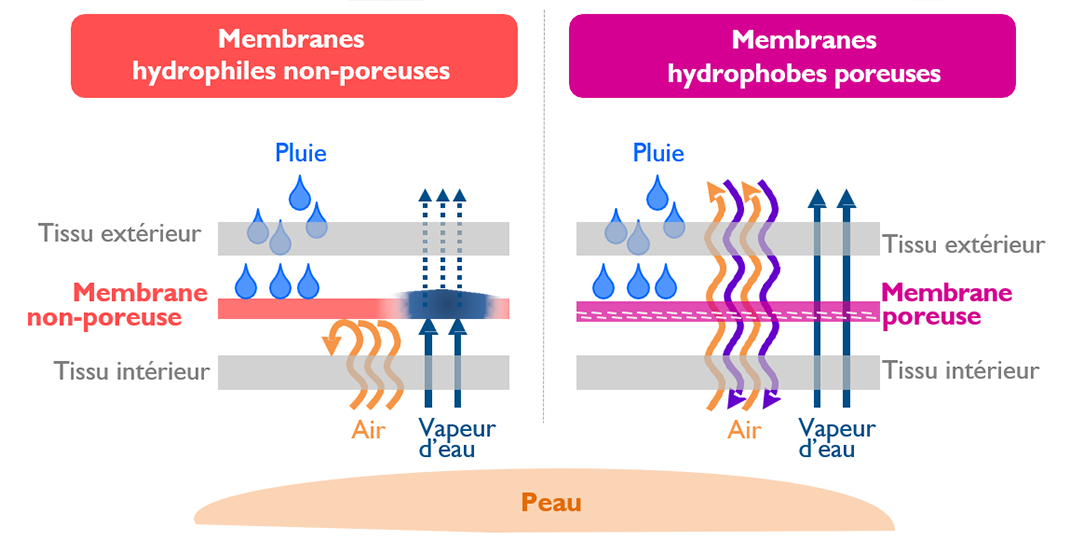

Simply put, there are two categories of waterproof-breathable membranes.

- Hydrophilic membranes provide a waterproof barrier and evacuate moisture through a process of water vapor absorption (they work like sponges). While effective in protecting the wearer from bad weather, they do not provide enough airflow for efficient breathability.

- Hydrophobic membranes also provide a waterproof barrier, but their microporous design proves much more efficient in wicking away sweat. The micropores allow for increased airflow, which translates to excellent breathability. Xpore belongs to this category of membranes, and is designed with nanopores that are even smaller and more efficient than micropores for maximum performance and breathability.

What does all this have to do with the environment?

While we often talk about the technical performance of a waterproof-breathable membrane, we rarely discuss its environmental characteristics. So in the name of transparency, what is Xpore?

Through its inherent design, the Xpore membrane proves incredibly “minimalist,” doing much more with much less. Simply put, we use less material than when creating traditional membranes and do not use solvents and chemical compounds like PFCs (perfluorocarbons) unlike other similar membranes. For more information about PFCs, click here.

Why is this so important?

Using solvents and PFCs is anything but trivial when it comes to worker health and the environment. For example, did you know that PFCs are greenhouses gases invented by humans? You read that right. Members of the halocarbon family, they contribute directly to global warming. As if we did not have enough work to do dealing with carbon dioxide and methane!

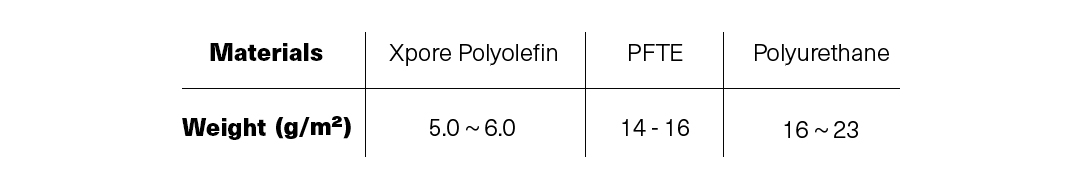

Here is the weight in g/m² of Xpore. Using a polyolefin material allows you to make a much lighter membrane.

What are the ways we can improve Xpore to make it even more sustainable?

First of all, let’s be clear about polyolefin, like all other membrane materials, it is a petroleum-based derivative. To further reduce our direct dependence on petroleum, we have started to work on using recycled polyolefin to make the Xpore membrane.

The other major area of improvement is energy use. What source of electricity powers the machines that make the membrane? While we do not have a precise answer to this question, we do know that the energy mix in China (the BenQ factory is located in China) depends heavily on coal, so the energy needed to manufacture the membrane in the short term still unfortunately depends on fossil fuels. Our goal is to “push” BenQ to take the same measures as at one of their other factories in Taiwan: transition to using renewable energy by installing solar panels to replace the fossil-fuel based electricity they currently depend on. This alone will significantly reduce the carbon emissions linked to producing the power the factory needs. To be continued…

These words embody the Picture’s sustainable vision for skiing and snowboarding. The new Xpore waterproof breathable membrane plays an integral part in our approach to ensuring that every freeride or backcountry session respects the natural environment where we choose to venture.

At a time when the textile industry is responsible for 8% of the world’s carbon emissions and where the climate emergency has reached its peak, we all have a role to play to effect change. This is why, since we started Picture in 2008, the brand has always sought to limit its impact on the environment as much as possible. Committed to taking an approach to business that is sustainable, ethical, and environmentally responsible, our brand considers every aspect of the process, from the supply chain, to production, to shipping.

How can we limit the negative effects business has on the climate and people? By wiping out our dependence on fossil fuels. Curbing business’s environmental impact and unstainable growth, changing traditional economic models for manufacturing, and promoting responsible consumption are the pillars to this evolution.

However, trying to go it alone would barely represent a drop in the bucket. This is where the B-Corp motto has real meaning: using business and the brand “as a force for good” to instigate the energy transition and decarbonization of the economy.

So, are you ready to take part?