Products Technology, Sustainability

From plastic bottles to snow jackets – 5/5

Article published on February 13, 2019

In October 2018, we traveled to Taiwan to retrace every step in the snow jacket manufacturing process, from recycling plastic bottles to making the finished product.

Episode #5: making a snow jacket.

After the first 4 steps in Taiwan, it is time to head to our partner factory, Li Lan, in Dongguan, China, 2 hours north of Hong Kong. We have been working with them from the outset, since Picture started in 2008.

In simple terms, making a snow jacket involves cutting the fabric into different pieces and then putting those pieces together.

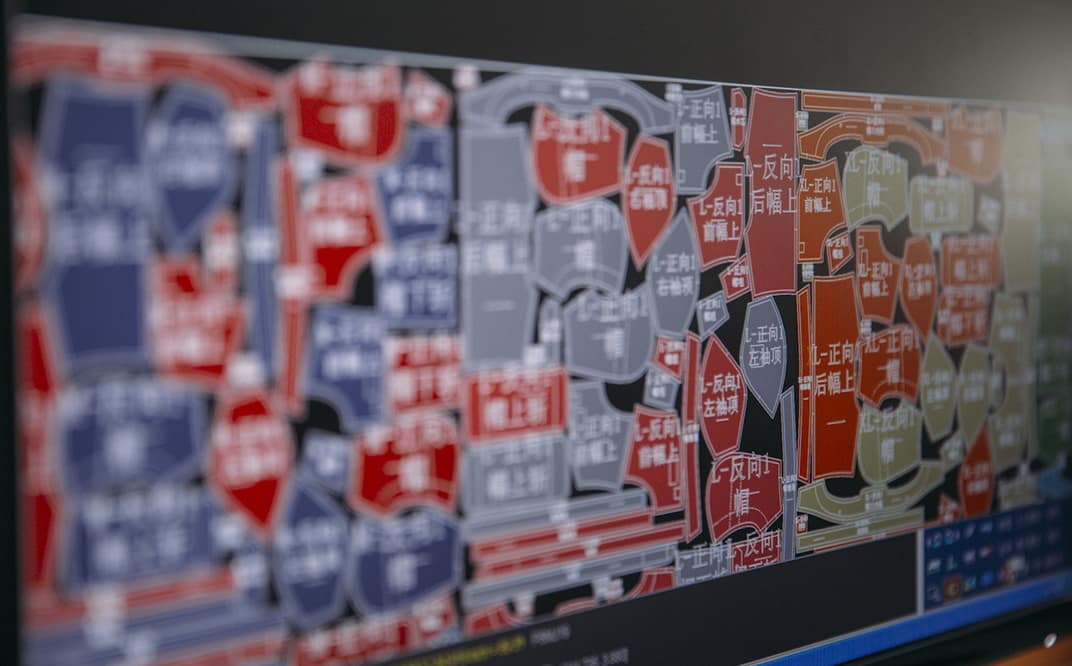

Marking the different pieces of a product (sleeves, front, back, hood, etc.) is done automatically on a computer with the goal of creating as little cut waste as possible.

The black sections in the photo represent cut waste. Efficiency is important to waste as little fabric as possible.

The pattern is printed:

Each piece is then cut by hand, with help from a machine.

The pattern (in white) is placed on the fabric. The worker follows the markings and cuts each piece (for example, the sleeves and hood).

Once every piece is cut, we need to sew them together.

However, seams are weak points where water can more easily seep in when it rains or snows. We use waterproof seam tape to solve this issue.

Applying waterproof tape to the seams.

We either tape all seams on our high-performance technical jackets or those seams most likely to leak in extreme weather on our other jackets.

Other components are added – such as the buttons, snow skirt, drawstrings, zippers, zipper sliders, etc. – during the process

Every step is done manually except for the laser cutting.

Once everything is sewn together, we inspect all of our products, checking the seams and testing every feature. We then iron and fold the jacket, place the labels and bar codes, and then package it.

The finished product. Object Jacket, Winter 2019/2020.

There you have it, from recycling plastic bottles to making the finished product, you now know everything!

We should also always keep in mind those who work behind the scenes to make our products. What exactly are conditions like in the factories where they work? To learn more, see you in April during Fashion Revolution Week.